Trusted by Industry Leaders

Trusted by Industry Leaders

Solutions

Solutions

Surface Inspection

Automatically detect and classify surface defects, including peeling, blow-outs, scoring, roll-ins, and flaking

Surface Inspection

Automatically detect and classify surface defects, including peeling, blow-outs, scoring, roll-ins, and flaking

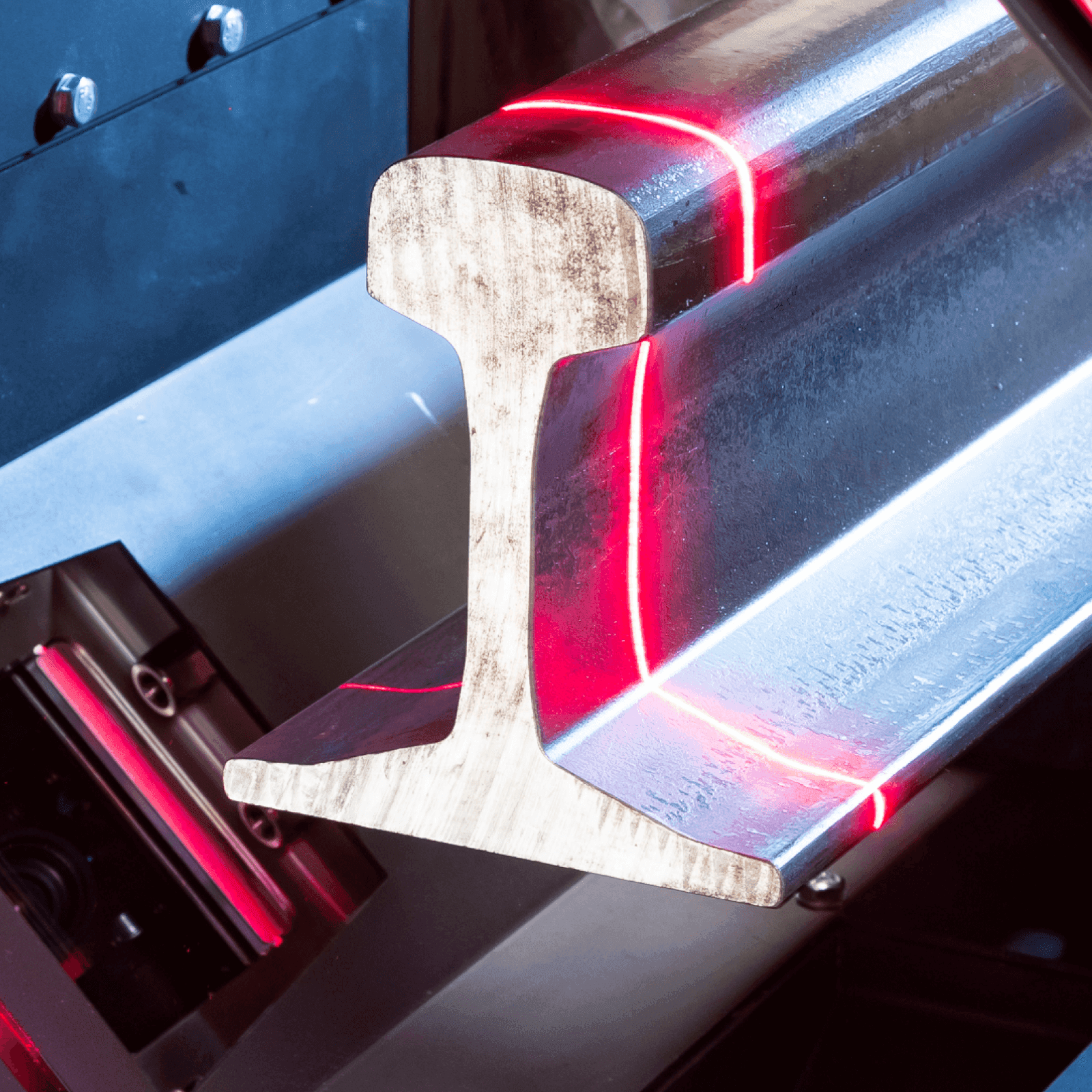

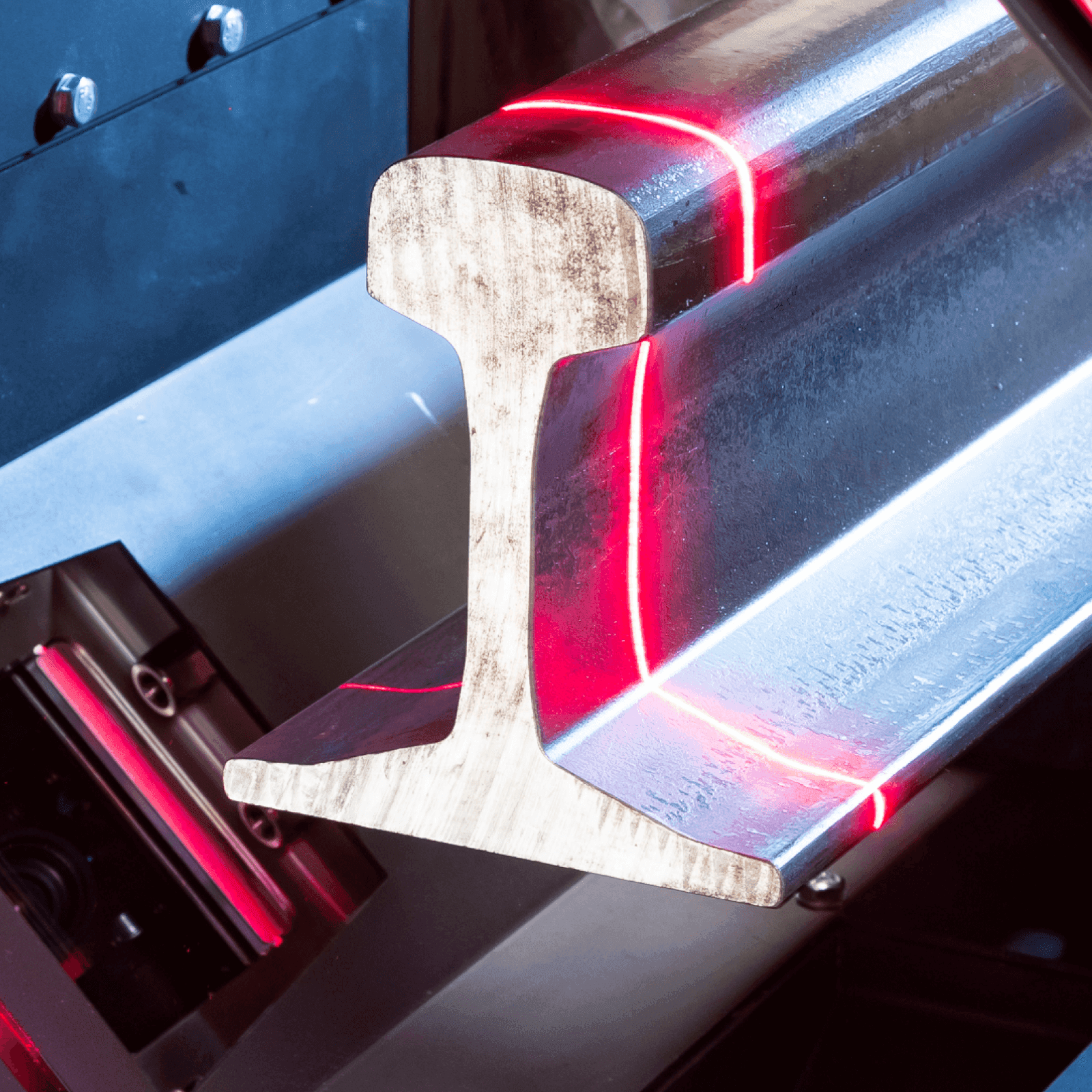

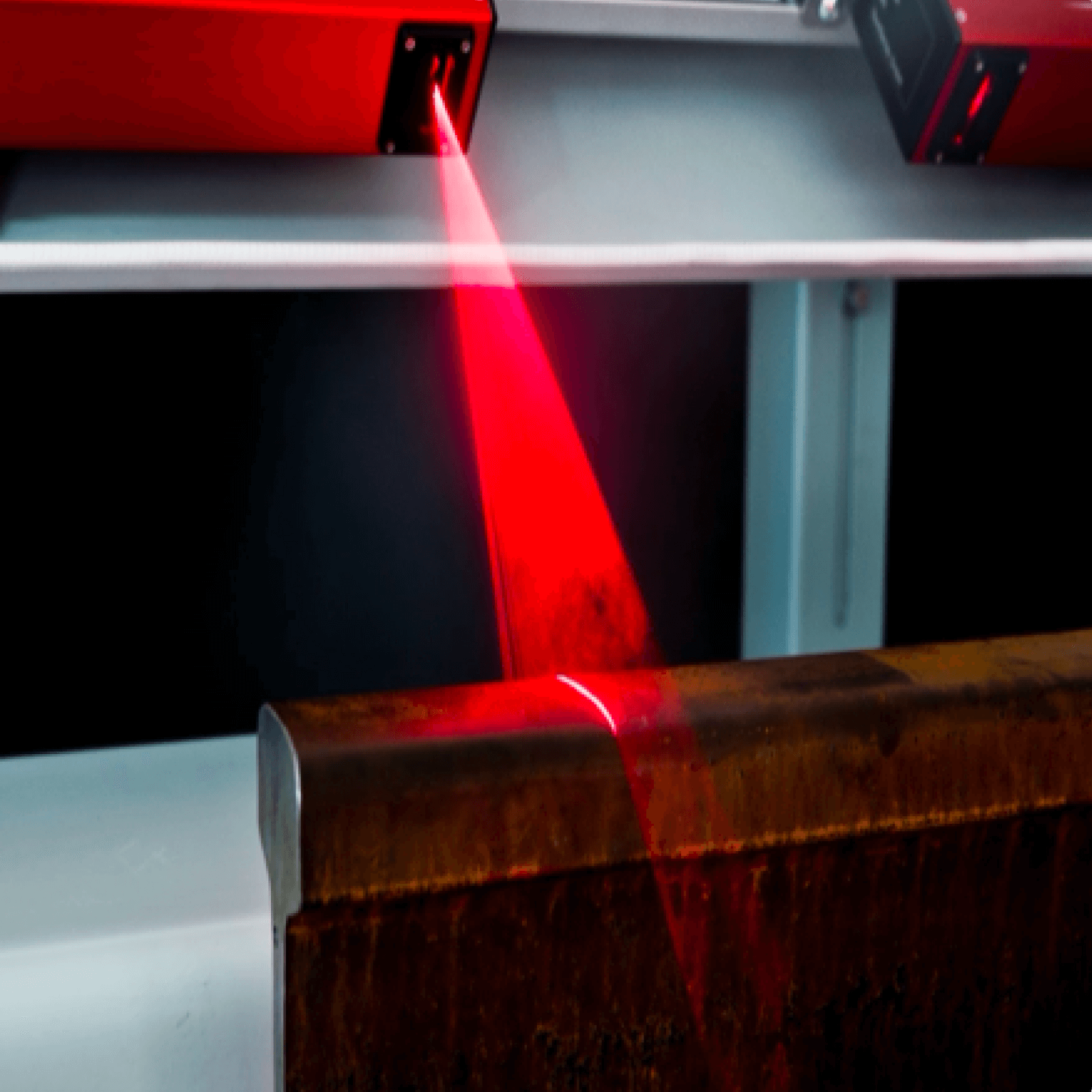

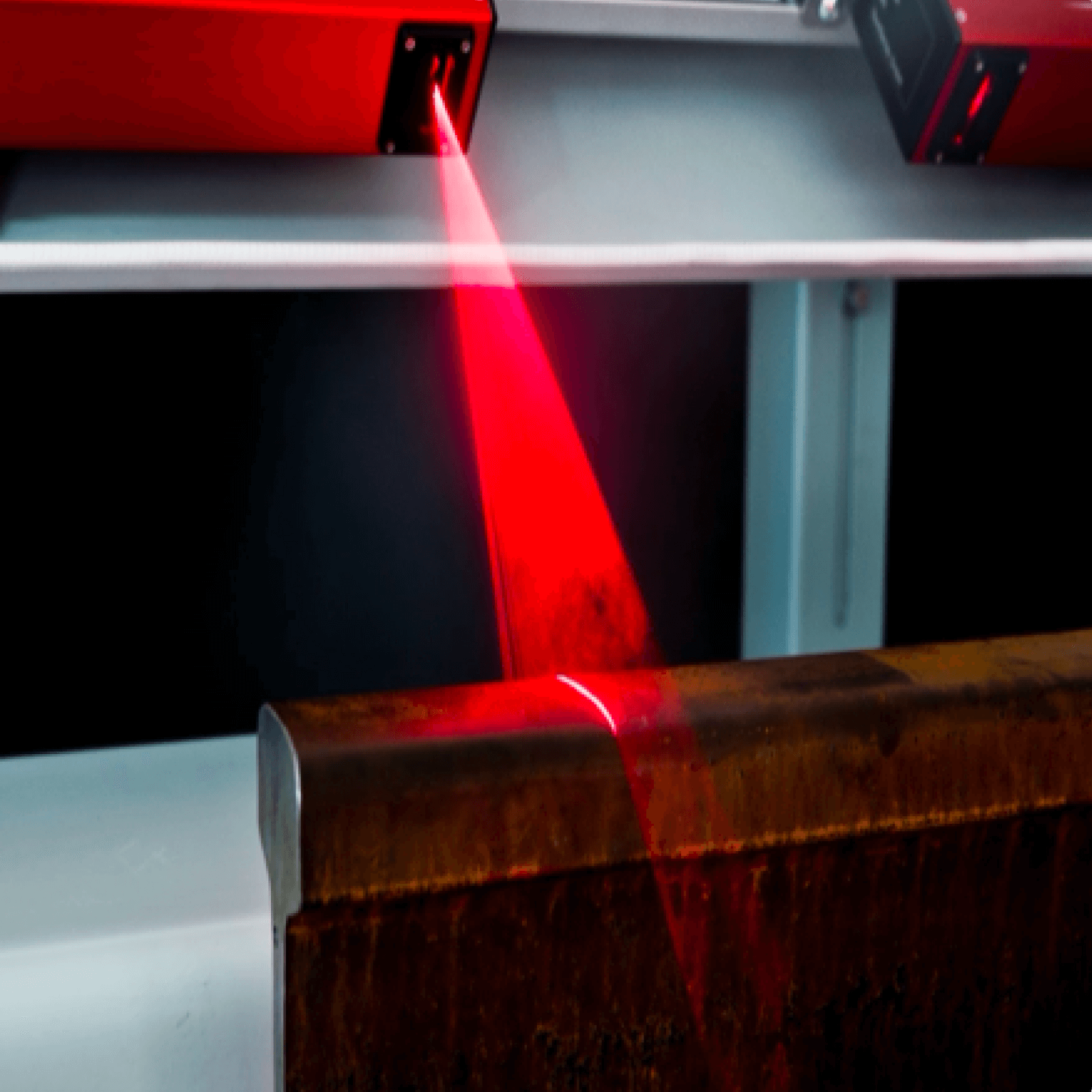

Profile Measurement

Automatically detect and classify surface defects, including peeling, blow-outs, scoring, roll-ins, and flaking

Profile Measurement

Automatically detect and classify surface defects, including peeling, blow-outs, scoring, roll-ins, and flaking

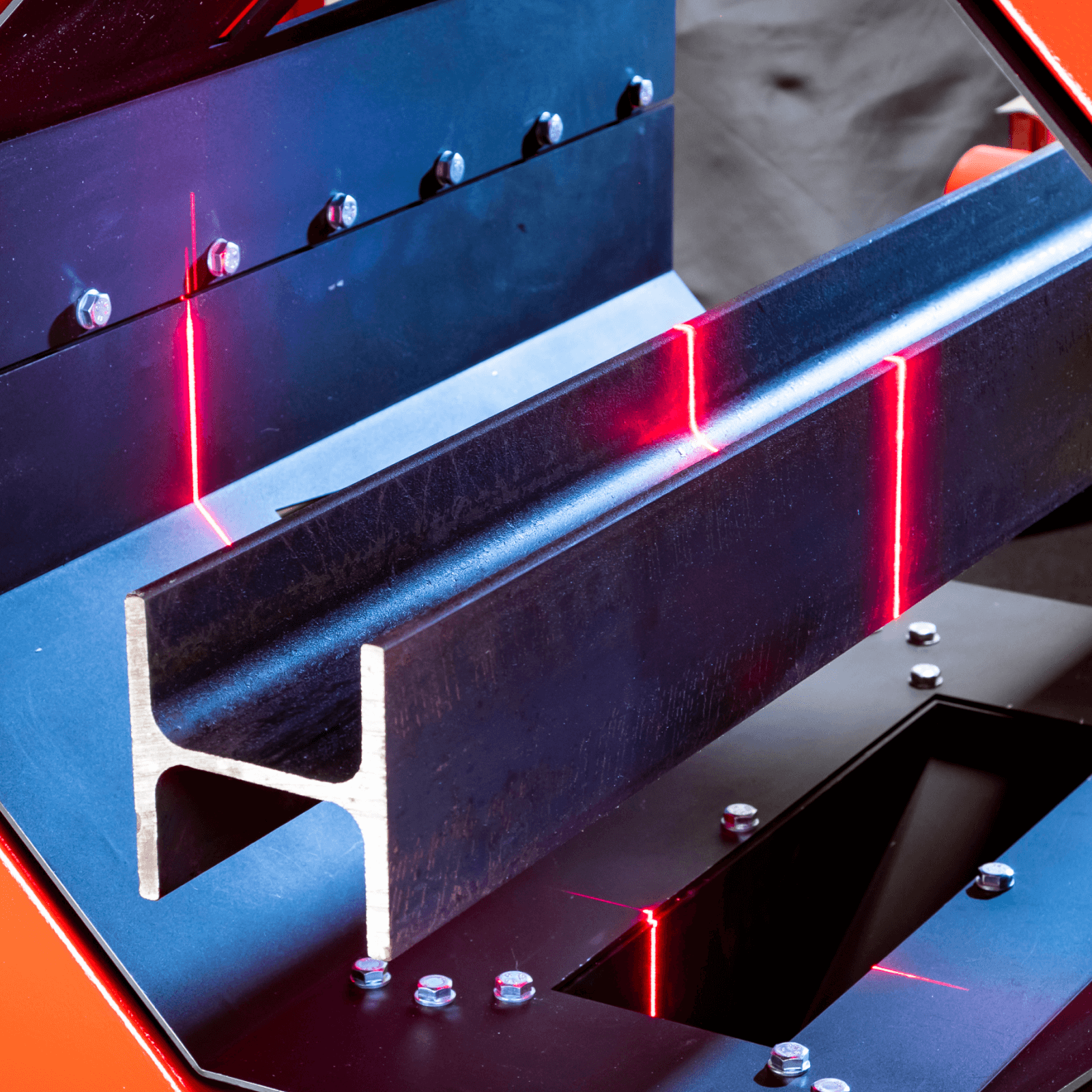

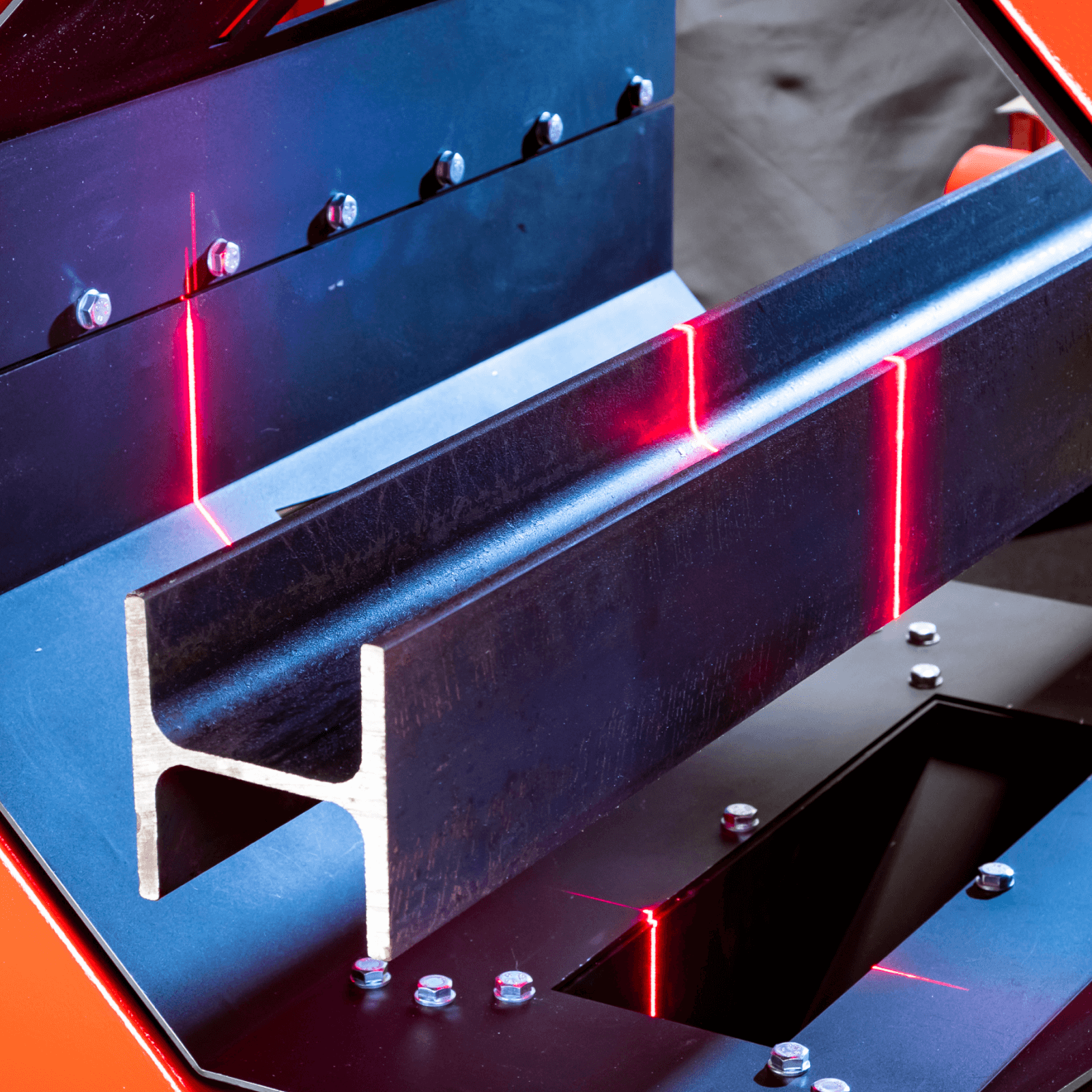

Flatness Measurement

Automatically detect and classify surface defects, including peeling, blow-outs, scoring, roll-ins, and flaking

Flatness Measurement

Automatically detect and classify surface defects, including peeling, blow-outs, scoring, roll-ins, and flaking

Our Portfolio

Our Portfolio

About us

About us

Teragon is an Austrian technology company that specialises in advanced laser measurement technology for steel rolling mills. Our product portfolio is the result of over 30 years of experience in the industry and an innovation partnership with Hexagon | NEXTSENSE.

Teragon is an Austrian technology company that specialises in advanced laser measurement technology for steel rolling mills.

Our product portfolio is the result of over 30 years of experience in the industry and an innovation partnership with Hexagon | NEXTSENSE.

»Sag' Servus«

Start a Conversation

»Sag' Servus«

Start a Conversation

© Teragon GmbH

2025

© Teragon GmbH